While the differences between the applications for an area scan machine vision camera vs. a line scan camera may often appear to be subtle, the differences in their technologies and the ways to optimize them in specific use cases is clear. By optimizing we include relative costs as well as imaging outcomes. This brief overview provides a foundational overview. For additional application engineering assistance please contact one of our industrial imaging technical consultants and get the support you need.

Definition of an Area Scan Camera:

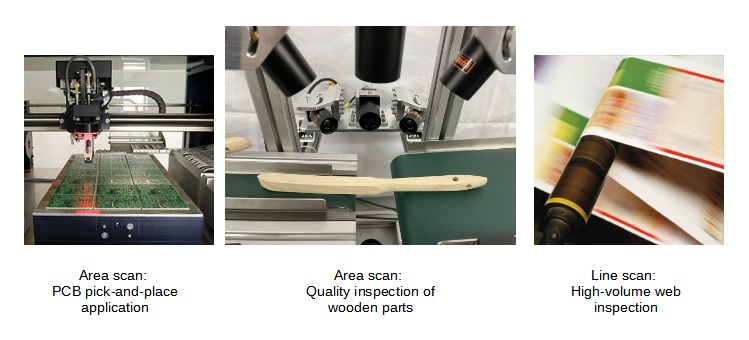

Area scan cameras are generally considered to be the all-purpose imaging solution as they use a straight-forward matrix of pixels to capture an image of an object, event, or scene. In comparison to line scan cameras, they offer easier setup and alignment. For stationary or slow moving objects, suitable lighting together with a moderate shutter speed can produce excellent images.

Even moving objects can become “stationary” from the perspective of an area scan camera through appropriate strobe lighting and/or a fast shutter speed, so just because something is motion does not necessarily disqualify an area scan solution.

Among the key features of an area scan camera include that the camera, when matched with a suitable lens, provide a fixed resolution. This allows for easy set up in imaging system applications where the cameras will not move after installation. Area scan cameras are also extremely flexible, as a single frame can be segmented into multiple regions-of-interest (ROI) to look for specific objects rather than having to process the entire image.

Additionally, some models of area scan cameras are optimized to be sensitive to infrared light, in portions of the spectrum not visible to the human eye. This allow for thermal imaging as well as feature identification applications that can be innovative and cost-effective, opening new opportunities for machine vision.

Definition of a Line Scan Camera:

In contrast to an area scan camera, in a line scan camera a single row of pixels is used to capture data very quickly. As the object moves past the camera, the complete image is pieced together in the software line-by-line and pixel-by-pixel.

Line scan camera systems are the recognized standard for high-speed processing of fast-moving “continuous”objects such as in web inspection of paper, plastic film, and related applications.. Among the key factors impacting their adoption in these systems is that the single row of pixels produced by line scanning allows the imaging processing system to build continuous images unlimited by a specific vertical resolution. This results in superior, high resolution images. Unlike area scan cameras, a line scan camera can also expose a new image while the previous image is still transferring its data. (Because the pixel readout is faster than the camera exposure.) When building a composite image, the line scan camera can either move over an object or have moving objects presented to it. Coordination of production/camera motion and image acquisition timing are critical for line scan cameras but, unlike area scan cameras, lighting is relatively simple.

What if you need to image a medical tube, or round object, such as a steel ball bearing?

In certain applications, line scan cameras have other specific advantages over area scan cameras. Consider this application scenario: You need to inspect several round or cylindrical parts and your typical system experience is with area scan cameras, so you set about to use multiple cameras to cover the entire part surface. It’s doable, but a better solution would be to rotate the part in front of a single line scan camera to capture the entire surface and allow the processor to “unwrap” the image pixel-by-pixel. Line scan cameras are also typically smaller than area scan. As a result, they sneak into tight spaces such as in a spot where they might have to peek through rollers on a conveyor to view a key angle of a part for quality assurance.

Not sure which area scan or line scan camera is right for you?

There are a host of options and tradeoffs to consider even after you’ve made your decision on the technology that’s likely best for you. 1st Vision is the US distributor you need. Our industrial imaging consultants are available to help you navigate the various camera models and brands from industry-leading manufacturers Teledyne DALSA, IDS, and Allied Vision.