What applications challenges can LWIR solve?

LWIR is the acronym, is it reminds us where on the electromagnetic spectrum we’re focused – wavelengths around 8 – 14 micrometers (8,000 – 14,000 nm). More descriptive is the term “thermal imaging”, which tells us we’re sensing temperatures not with a contact thermometer – but using non-contact sensors detecting emitted or radiated heat.

Security, medical, fire detection, and environmental monitoring are common applications. More on applications further below. But first…

How does an LWIR camera work?

Most readers probably come to thermal imaging with some prior knowledge or experience in visible imaging. Forget all that! Well not all of it.

For visible imaging using CMOS sensors, photons enter pixel wells and generate a voltage. The array of adjacent pixels are read out as a digital representation of the scene passed through the lens and onto the sensor, according to the optics of the lens and the resolution of the sensor. Thermal camera sensors work differently!

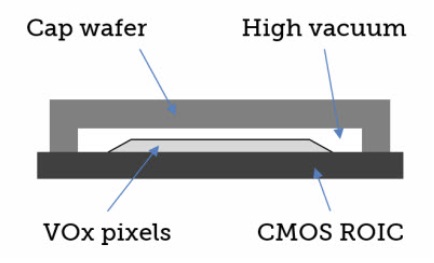

Thermal cameras use a sensor that’s a microbolometer. The helpful part of the analogy to a CMOS sensor is there we still have an array of pixels, which determines the resolution of the camera, as a 2D digital representation of the scene’s thermal characteristics.

But unlike a CMOS sensor whose pixels react to photons, a microbolometers upper pixel surface, the detector, is comprised of IR absorbing material, such as Vanadium oxide. The detector is heated by the IR exposure, and the intensity of exposure in turn changes the electrical resistance. The change in electrical resistance is measured and passed by an electrode to a silicon substrate and readout integrated circuit.

Just as with visible imaging, for machine vision it’s the digital representation of the scene that matters, as it’s algorithms “consuming” the image in order to take some action: danger vs. safe; good part vs. bad part; steer left, straight, or right – or brake; etc. Whether one generates a pseudo-image for human consumption may well be unnecessary – or at least secondary.

Applications in LWIR

Applications include but are not limited to:

- Security e.g. intrusion detection

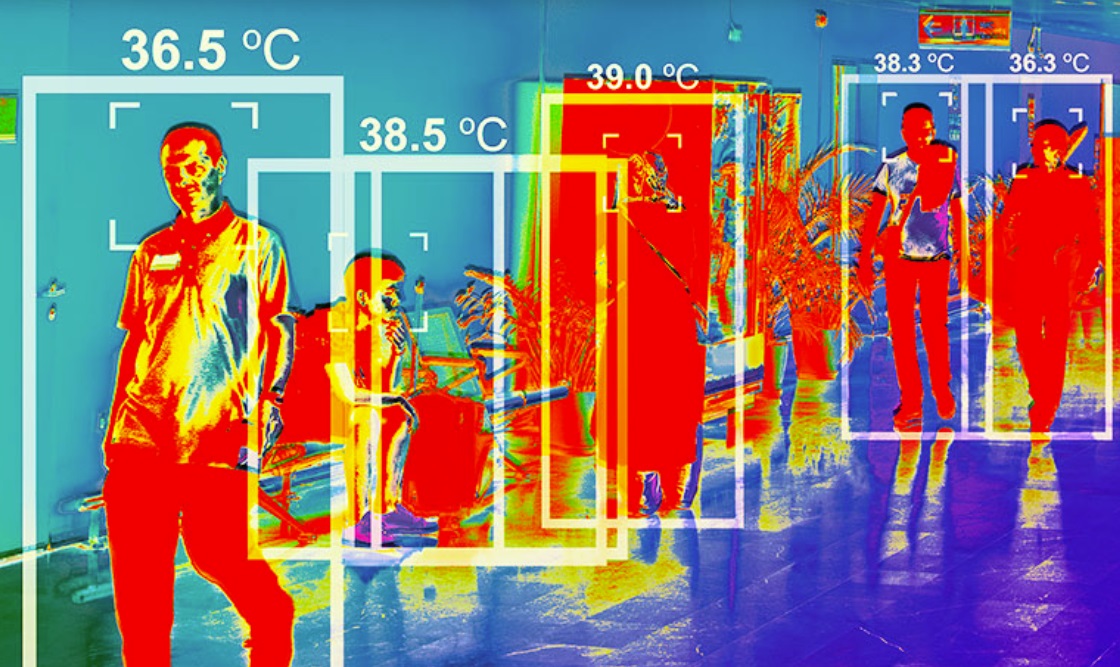

- Health screening e.g. sensing who has a fever

- Fire detection – detect heat from early combustion before smoke is detectable

- Building heat loss – for energy management and insulation planning

- Equipment monitoring e.g. heat signature may reveal worn bearings or need for lubrication

- Food safety – monitor whether required cooking temperatures attained before serving

You get the idea – if the thing you care about generates a heat signature distinct from the other things around it, thermal imaging may be just the thing.

What if I wanted to buy an LWIR camera?

We could help you with that. Does your application’s thermal range lie between -25C and +125C? Would a frame rate of 30fps do the job? Does a GigEVision interface appeal?

It’s likely we’d guide you to Teledyne DALSA’s Calibir GX cameras.

Precision of Teledyne DALSA Calibir GX cameras

Per factory calibration, one already gets precision to +/- 3 degrees Celsius. For more precision, use a black body radiator and manage your own calibration to +/- 0.5 degrees Celsius!

Thresholding with LUT

Sometimes one wants to emphasize only regions meeting certain criteria – in this case heat-based criteria. Consider the following image:

Teledyne DALSA Calibir GX control software let’s users define their own lookup tables (LUTs). One may optionally show regions meeting certain temperatures in color, leaving the rest of the image in monochrome.

Dynamic range

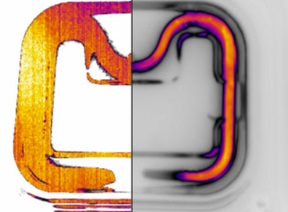

The “expressive power” of a camera is characterized by dynamic range. Just as the singers Enrico Caruso (opera) and Freddie Mercury (rock) were lauded for their range as well as their precision, in imaging we value dynamic range. Consider the image below of an electric heater element:

The left side of the image if from a 3rd party thermal imager – it’s pretty crude essentially showing just hot vs. not-hot, with no continuum. The right side was obtained with a Teledyne DALSA Calibir GX – there we see very hot, hot, warm, slightly warm, and cool – a helpfully nuanced range. Enabled by a 21 bit ADC, the Teledyne DALSA Calibir GX is capable of a dynamic range across 1500°C.

In this short blog we’ve called out just a few of the available features – call us at 978-474-0044 to tell us more about your application goals, and we can guide you to whichever hardware and software capabilities may be most helpful for you.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of cameras, lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!

About you: We want to hear from you! We’ve built our brand on our know-how and like to educate the marketplace on imaging technology topics… What would you like to hear about?… Drop a line to info@1stvision.com with what topics you’d like to know more about.