For machine vision purposes, we generally advise against using F-mount. We don’t have a dog in the hunt for leisure or artistic photography, but for reliability in many machine vision applications there are shortcomings with F-mounts.

Even our premier partner Schneider Optics, produces very fine F-mount lenses – the optics are first class! But just as a reliable auto dealership would counsel against buying a compact sedan to tow a heavy boat, we would hope to engage you in dialogue about your imaging application – and help you choose the best lens.

There are many lens mounts available

The wide range of lens mounts is, generally speaking, a very good thing. It permits camera designers and manufacturers to specialize in what they are good at; and likewise for lens designers and their own production facilities. The former is electronics while the latter is about optics.

By defining standards for lens mounts, we all benefit from market competition, which drives quality, feature, and price differentiation.

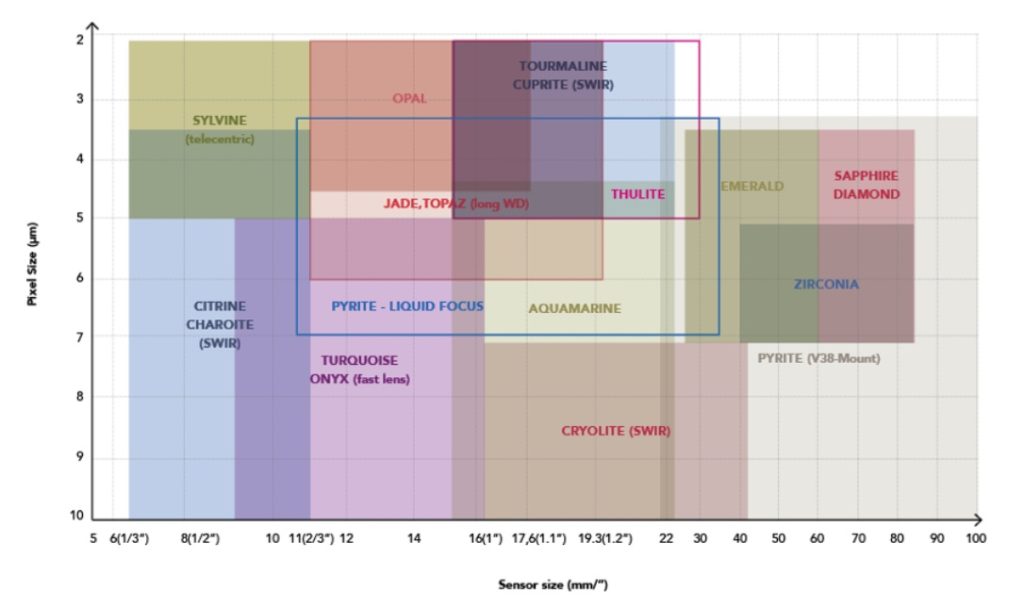

Some mounts are for large-format sensors. Some for small sensors. Some for “quick change”. Some for stability. Some can fit several niches. Some can in theory but shouldn’t be pushed in practice. Below we provide examples.

What should we consider with F-mounts?

If you are a sports photographer, F-mount may be an excellent choice. The bayonet mount design is ideal for quick lens changes, and the “money shot” may require a quick lens swap. If shooting at really short exposure times, inherent instability in the mount design may not have an impact on image quality.

While the F-mount name traces to the famous Nikon F camera series, one might also think of it as for “Fotographie” – the German work for photography – if you like mnemonic hints.

But for machine vision applications, one typically mates the lens to the camera “forever”, so quick-change benefits are of little value. And compared to screw mounts, for example, it’s clear that the bayonet mount, with just two securing points, might suffer in a high-vibration environment. Whether on the factory floor, a traffic camera gantry, or a moving vehicle, the lens and camera should act as one. Stability is key.

For the record, F-mount defines a standard Flange Distance of 46.5mm from the mounting surface of the camera to the sensor, as well as standardized mechanics on the size and position of the male pins on the lens and the female receptors on the camera body. For those cameras or lenses with electrical contacts as well, there are variances. But mechanically and optically and F-mount is an F-mount.

What about the M42 lens mount?

While the M42 lens mount came into existence for “photography”, when computers and then machine vision emerged, M42 has become one of many popular lens mounts. The threaded screw mount design provides a very secure connection that binds along several turns of the screw – so it’s very resistant to vibration.

But while the conceptual design is great, M42 isn’t really a “full standard” in two important ways…

M42 doesn’t define flange distance

Every lens must precisely focus light rays onto the sensor surface. Camera makers position sensors a precise distance from the shoulder of the mount, a distance referred to as the flange distance, or flange focal distance. Curiously, there isn’t universal agreement on what that distance should be – though there is some convergence on a couple of de facto conventions.

The M42 lenses may need to have an extension tube added so that they can image on a camera sensor. Thankfully an extension tube is an inexpensive but effective accessory – but it’s important to note focal distances and source components accordingly.

M42 doesn’t define thread pitch

The second caveat with M42 mounts is that there are at least two common thread pitches offered: both 0.75 and 1.0.

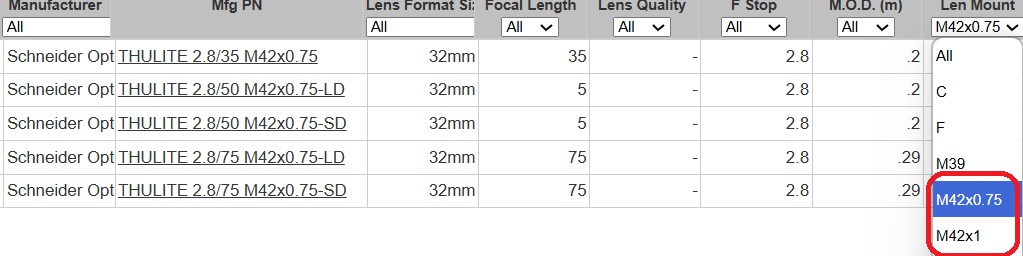

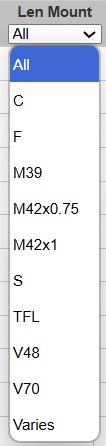

If we use the 1stVision lens-selector, the Lens Mount dropdown shows both M42x0.75 as well as M42x1 options (as well as many other lens mounts). So if you know the camera mount specifications, you can find lenses that will thread correctly – but one needs to pay attention!

All the mounts we offer

To the left is a snapshot from the 1stVision lens-selector, showing the dropdown for all lens mounts we offer. If one chooses “All” it yields some 200 lenses across more than 10 manufacturers.

By specifying the lens mount, for the camera you are considering, one need only select a couple of additional dropdowns like sensor format, and focal length, to home in on candidate lenses for your application.

Each mount has its role. While a camera designer sometimes has options relative to sensor size, intended market, and price : performance decisions, there are good reasons why each mount type exists. And while some cameras are available with two or more mount options, generally speaking the camera you choose will dictate the mount – and hence the lens options.

Don’t fixate on the mount

While we’ve discussed certain aspect of lens mounts in this blog, you can generally trust that camera designers have chosen a suitable one for any particular camera – after all they want to maximize the number of cameras they can sell. There are many other considerations in machine vision lens selection. You can read all about it, or just…

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of cameras, lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!

About you: We want to hear from you! We’ve built our brand on our know-how and like to educate the marketplace on imaging technology topics… What would you like to hear about?… Drop a line to info@1stvision.com with what topics you’d like to know more about