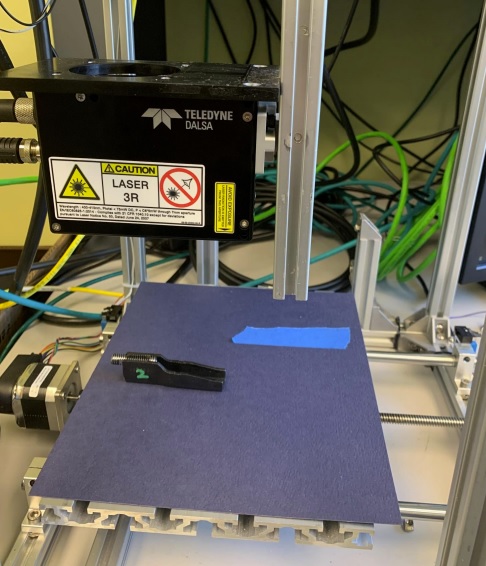

Ideal for industrial applications requiring precision, reliability, high speed, and high resolution, AT Sensors (previously known as Automation Technology) XCS 3D sensor laser profiler 3070 WARP achieves speeds up to 200 kHZ with the dual head model. Even the single head can achieve 140 kHz. The key innovations in the XCS series are in the laser-line projection technology.

Aren’t all 3D sensor laser profilers similar?

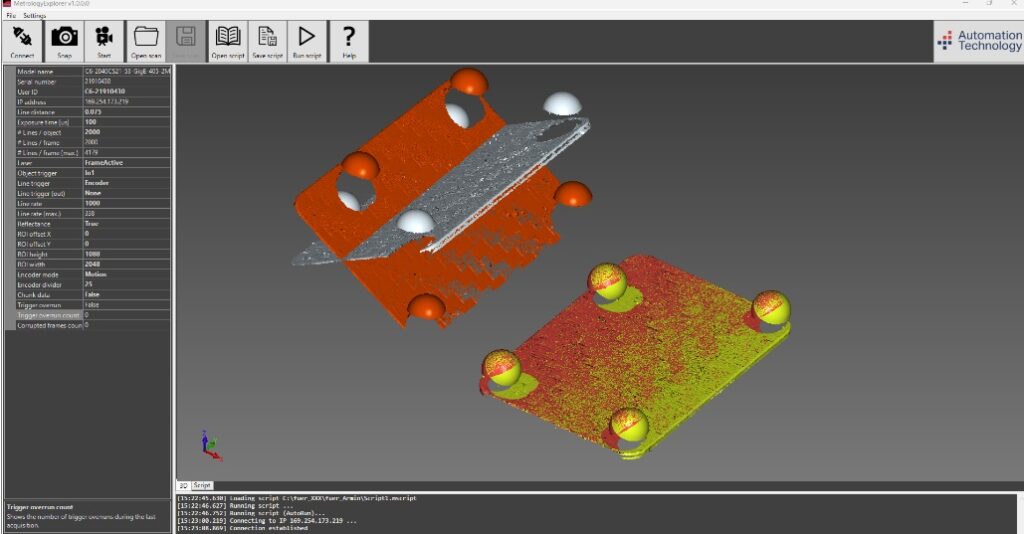

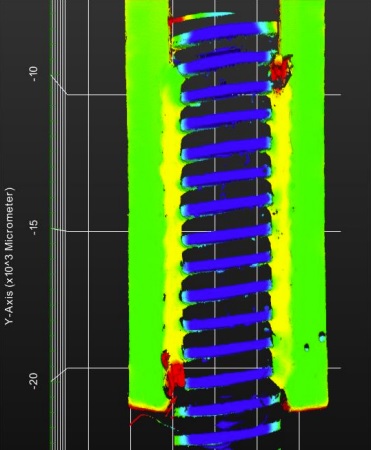

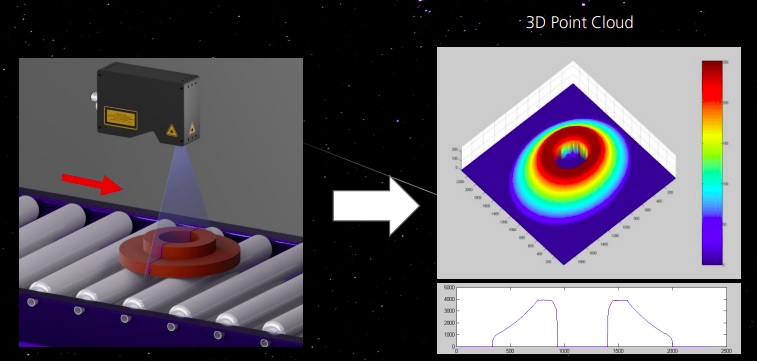

Many indeed share underlying similarities. Often they use triangulation to make their measurement. And the output is a 3D profile (or point cloud) of a target, built up by rapid laser pulsed stepwise “slices” of the X dimension as the target (or sensor) moves in the Y dimension. Triangulation determines variances in the Z dimension based on how the laser angle reflects from the target surface coordinate onto the sensor. For a brief refresher on the concepts, see our overview article and illustrations.

What’s special about AT Sensors XCS Series?

Key attributes are shown in the video and called out in the following text.

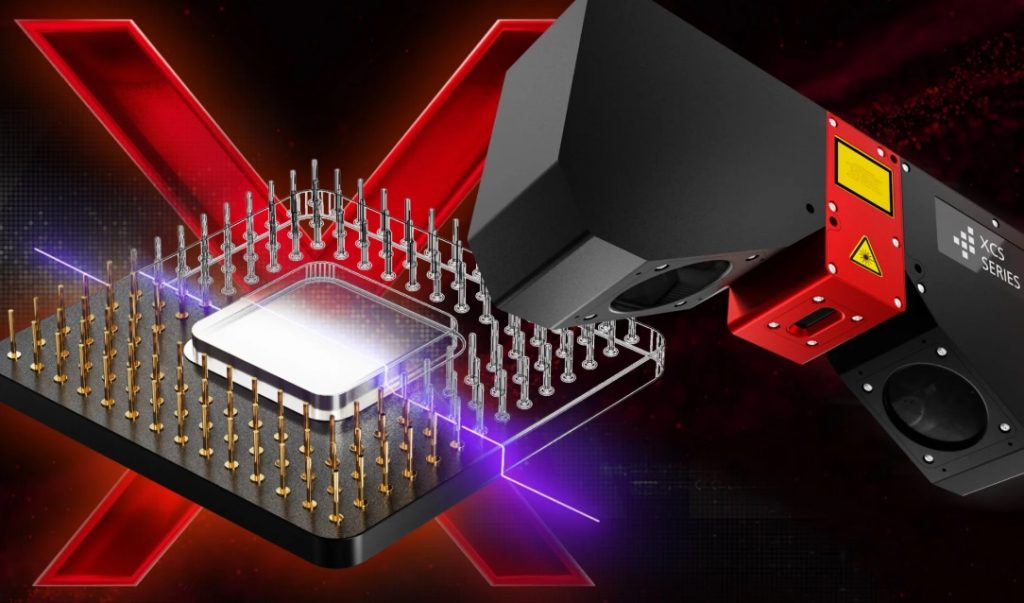

Homogeneous thickness laser line

Using special optics, the XCS series projects a laser line of homogeneous thickness across the target surface. AT Sensors uses Field Curvature Correction (FCC) to create the uniform projection, overcoming the so-called line “bow” effect. This enables precise scanning of even small structures – regardless of whether such features are in the middle or edge of the laser line. What’s the benefit for the customer? It enables applications with high repeatability and accuracy – such as for ball grid arrays (BGAs), pin grid arrays (PGAs), and surface mount devices (SMDs).

Clean Beam Technology

The XCS Series utilizes AT Sensors own Clean Beam function to insure a precisely focused laser beam, effectively suppressing side lobe noise interference.. Clean Beam also assures a uniform intensity distribution, which also contributes to the reliably consistent results.

Optional Dual Head to avoid occlusion

X FOV 53mm +/-

X Resolution 13mm +/-

Z Range to 20mm

Z Resolution to 0.4 µm

GigE Vision interface, GenICam compliant

For plug and play configuration with networking cables and adapter cards familiar to many, the GigE Vision interface is one of the most popular machine vision standards. And GenICam compliance means you can use AT – Automation Technology’s software or diverse 3rd party SDKs.

Additional features

Automatic RegionTracking, Automatic RegionSearch, Multiple Regions, MultiPart, AutoStart, History Buffer, Multi-Slope, MultiPeak

Is the XCS 3D sensor laser profiler best for your application?

AT Sensors is confident there are demanding users for whom the XCS 3D laser profiler delivers just the right value proposition. Is that what your application requires? But AT also provides 3 other product families of laser profilers, including the CS Series, the MCS Series, and the ECS Series. It all comes down to speed and resolution requirements, field of view (FOV), and cost.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of cameras, lenses, cables, NIC cards and industrial computers, we can provide a full vision solution!

About you: We want to hear from you! We’ve built our brand on our know-how and like to educate the marketplace on imaging technology topics… What would you like to hear about?… Drop a line to info@1stvision.com with what topics you’d like to know more about.