In this article we discuss when and why one might want to strobe a light instead of using continuous lighting. While strobing traditionally required a dedicated controller, we go on to introduce that CCS and AVT have published an Application Note showing how the Allied Vision Mako camera can serve as the controller!

While LED lights are often used for continuous lighting, since that’s an easy mode of deployment, sometimes an application is best served with a well-timed strobe effect. This might be for one or more of the following reasons:

- to “freeze motion” via light timing rather than shutter control alone;

- to avoid the heat buildup from continuously-on lights

- overwhelm ambient lighting

- maximize lamp lifetime

Let’s suppose you’ve already decided that you require strobe lighting in your application. You’re past “whether” and on to “how to”.

Since you are moving into the realm tight timing tolerances, it’s clear that the following are going to need to be coordinated and controlled:

- the strobe light start and stop timing, possibly including any ramp-up delays to full intensity

- the camera shutter or exposure timing, including any signal delays to start and stop

- possibly the physical position of real world objects or actuators or sensors detecting these

Traditionally, one used and external controller, an additional device, to control both the camera and the lighting. It’s a dedicated device that can be programmed to manage the logical control signals and the appropriate power, in the sequence required. This remains a common approach today – buy the right controller and configure it all, tuning parameters through calculations and empirical testing.

Call us if you want help designing your application and choosing a controller matched to your camera and lighting requirements.

But wait! Sometimes, thanks to feature-rich lighting equipment and cameras, with the right set of input/output (I/O) connections, and corresponding firmware-supported functionality, one can achieve the necessary control – without a separate controller. That’s attractive if it can reduce the number of components one needs to purchase. Even better, it can reduce the number of manuals one has to read, the number of cables to connect, and the overall complexity of the application.

Let’s look at examples of “controller free” applications, or more accurately, cameras and lights that can effect the necessary controls – without a separate device.

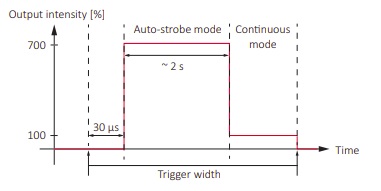

Consider the following timing diagram, which shows the behavior of the Effi-Ring when used in auto-strobe mode. That doesn’t mean it strobes randomly at times of its own choosing! Rather it means that when triggered, it strobes at 300% of continuous intensity until the trigger pulse falls low again, OR 2 seconds elapse, whichever comes first. Then if steps down to continuous mode at 100% intensity. This “2 seconds max” feature, far longer than most strobed applications require, is a design feature to prevent overheating.

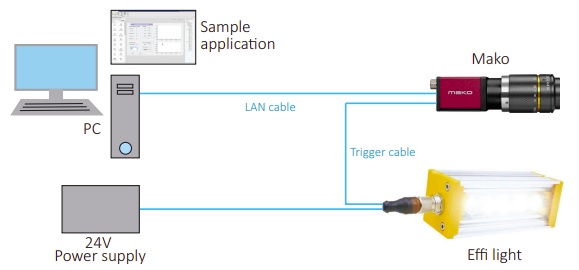

OK, cool. So where to obtain that nice square wave trigger pulse? Well, one could use a controller as discussed above. But in the illustration below, where’s the controller?!? All we see are the host computer, an Allied Vision Mako GigE Vision camera, an Effilux LED, a power supply, and some cabling.

How is this achieved without a controller? In this example, the AVT Mako camera and the Effilux light are “smart enough” to create the necessary control. While neither device is “smart” in the sense of so-called smart cameras that eliminate the host computer for certain imaging tasks, the Mako is equipped with opto-isolated general purpose input output (GPIO) connections. These GPIOs are programmable along with many other camera features such as shutter (exposure), gain, binning, and so forth. By knowing the desired relationship between start of exposure, start of lighting, and end of exposure, and the status signals generated for such events, one can configure the camera to provide the trigger pulse to the light, so that both are in perfect synchronization.

Note: During application implementation, it can be helpful to use an oscilloscope to monitor and tune the timing and duration of the triggers and status signals.

Whether your particular application is best served with a controller, or with a camera that doubles as a controller, depends on the application and camera options available. 1stVision carries a wide range of Effilux LED lights in bar, ring, backlight, and dome configurations, together with the ability to be used on continuous or strobe modes.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of lenses, cables, NIC card and industrial computers, we can provide a full vision solution!

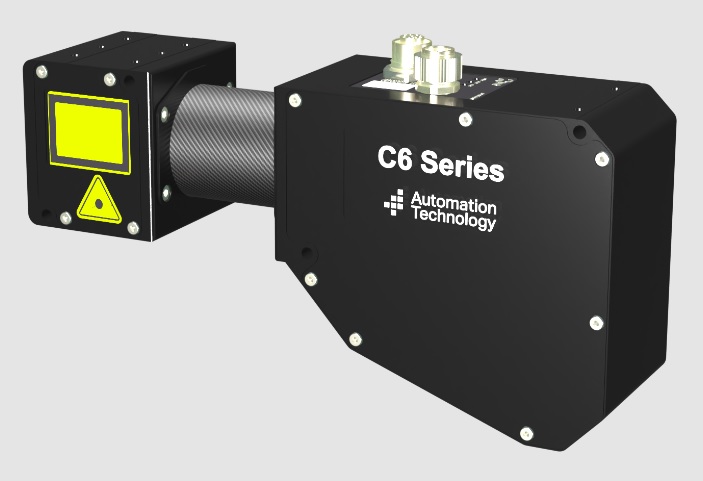

When new technologies or product offerings are introduced, it can help get the creative juices flowing by seeing example applications. In this case, 3D laser triangulation isn’t new, and

When new technologies or product offerings are introduced, it can help get the creative juices flowing by seeing example applications. In this case, 3D laser triangulation isn’t new, and