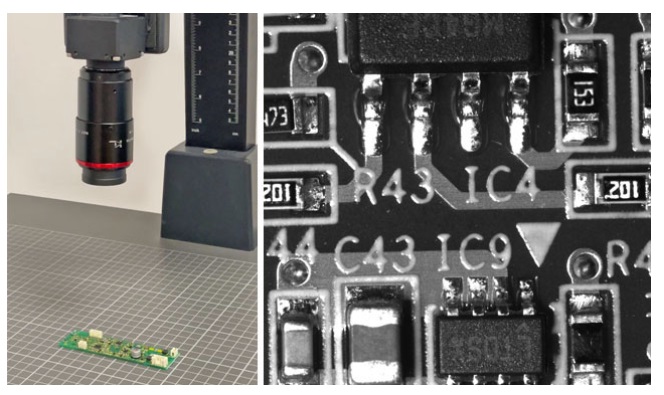

With 9 members in the Kowa FC24M lens series, focal lengths range from 6.5mm through 100mm. Ideal for sensors like the 1.1″ Sony IMX183, 530/540, 253 and IMX304, these C-mount lenses cover any sensor up to 14.1mm x 10.6mm, with no vignetting. Their design is optimized for sensors with pixel sizes as small as 2.5µm – but of course work great on pixels larger than that as well.

Lens selection

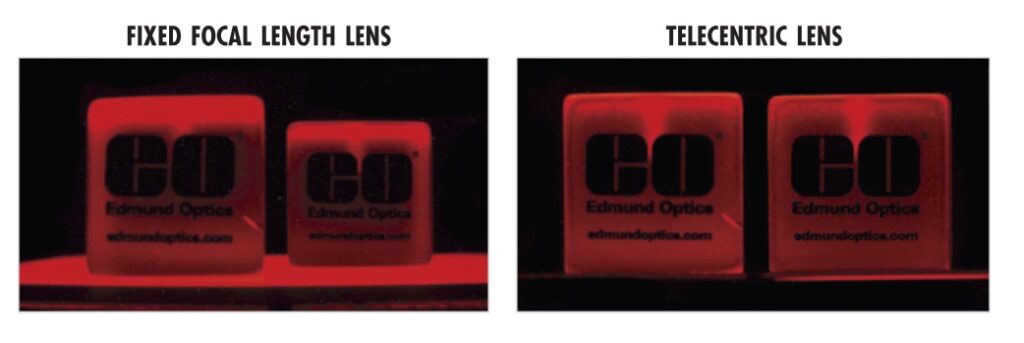

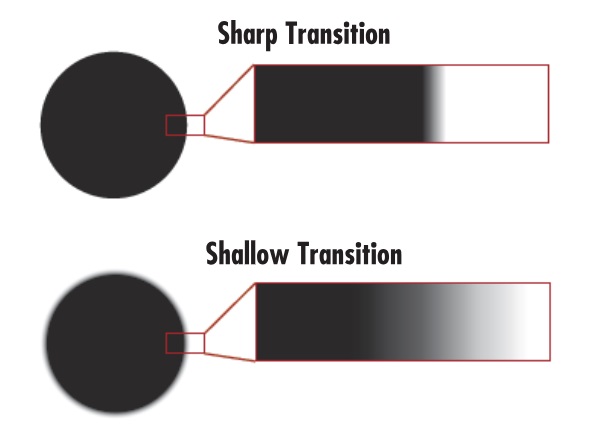

Machine vision veterans know that lens selection ranks right up there with camera/sensor choice, and lighting, as determinants in application success. For an introduction or refresher, see our knowledge base Guide to Key Considerations in Machine Vision Lens Selection.

Noteworthy features

Particularly compelling across the Kowa FC24M lens series is the floating mechanism system. Kowa’s longer name for this is the “close distance aberration compensation mechanism.” It creates stable optical performance at various working distances. Internal lens groups move independently of each other, which optimizes alignment compared to traditional lens design.

Listing all the key features together:

- Floating mechanism system (described above)

- Wide working range… and as close at 15 cm MOD

- Durable construction … ideal for industrial applications

- Wide-band multi-coating – minimizes flare and ghosting from VIS through NIR

Video overview shows applications

Applications include manufacturing, medical, food processing, and more. View short one-minute video:

What’s in a family name?

Let’s unpack the Kowa FC24M lens series name:

F is for fixed. With focal lengths at 9 step sizes from 6 – 100, lens design is kept simple and pricing is correspondingly competitive.

C is for C-mount. It’s one of the most popular camera/lens mounts in machine vision, with a lot of camera manufacturers offering diverse sensors designed in to C-mount housings.

24M is for 24 Megapixels. Not so long ago it was cost prohibitive to consider sensors larger than 20M. But as with most things in the field of electronics, the price : performance ratio keeps moving in the user’s favor. Many applications benefit from sensors in this size.

And the model names?

Model names include LM6FC24M, LM8FC24M, …, LM100FC24M. So the focal length is specified by the digit(s) just before the family name. i.e. the LM8FC24M has a focal length of 8mm. In fact that particular model is technically 8.5mm but per industry conventions one rounds or truncates to common de facto sizes.

See the full brochure for the Kowa FC24M lens series, or call us at 978-474-0044.

1st Vision’s sales engineers have over 100 years of combined experience to assist in your camera and components selection. With a large portfolio of cameras, lenses, cables, NIC cards and industrial computers, we can provide a full vision solution! We’re big enough to carry the best cameras, and small enough to care about every image.

About you: We want to hear from you! We’ve built our brand on our know-how and like to educate the marketplace on imaging technology topics… What would you like to hear about?… Drop a line to info@1stvision.com with what topics you’d like to know more about.