The AR1820HS Image sensor 18 mega pixel sensor in the IDS Imaging IDS Imaging UI-3590 camera models was launched by the sensor manufacturer ON Semiconductor as a pure color sensor. Like all color sensors, the Bayer filter means that you get color images with effectively only around a quarter of the nominal sensor resolution, as the color information for each pixel is obtained from four neighbors

To use each individual pixel, however, it is not sufficient to operate the sensor in RAW data format (without Bayer interpolation). Operating in a raw format results in a different brightness perception of the individual pixels and NOT a usable image.

This technical tip will show you how to use the color sensor as a “pure” mono sensor by appropriate parameter settings and the use of suitable light sources, in order to obtain a significantly higher resolution.

Applications which require a color image and precision will benefit from this camera and method.. and all for less than $600 with the IDS UI-3590LE camera

Background

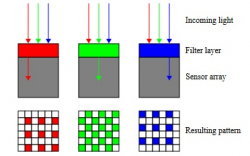

The principle of digital image sensors such as the 18 MP ON Semiconductor AR1820HS means that they acquire only brightness, but not color information.

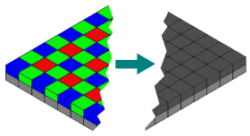

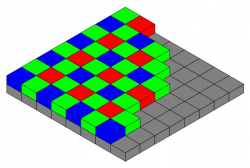

As a result, a color filter is applied to each pixel during manufacture of the color sensors. This is known as the Bayer matrix.

Of each four pixels, two pixels are given a green color filter, one pixel a red filter and one pixel a blue color filter. This color distribution corresponds to the perception of the human eye and is referred to as the Bayer matrix.

a particular wavelength

A pixel depicts only the information for one color.

To obtain the complete RGB values for each pixel, the missing primary colors are interpolated from four neighboring pixels using appropriate algorithms. This color interpolation assumes that there are only slight color differences between two adjacent pixels of the same color. Strictly speaking, a sensor with Bayer matrix therefore has only a quarter of the native sensor resolution

Sensor mono mode

Although the Bayer matrix cannot simply be rendered invisible for mono mode, the following two solutions show how you can achieve the desired result depending on the type of application.

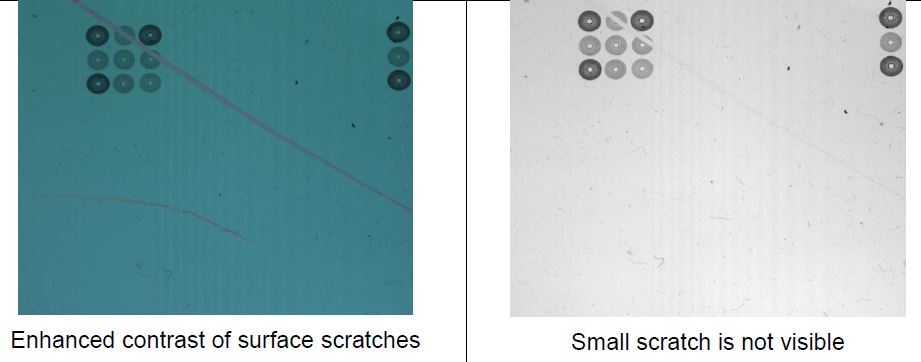

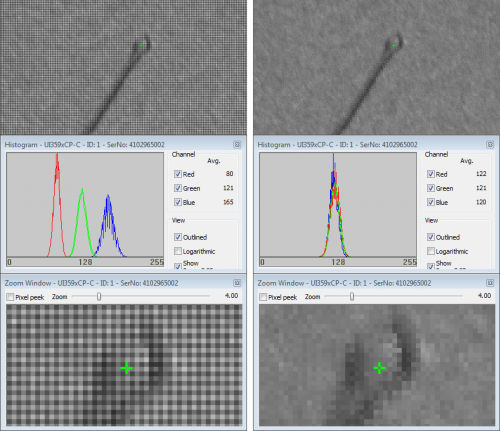

1) For “grey scenes” (i.e. dark pin on a white background)

If the 18 MP color sensor is to be used in mono mode for achromatic scenes, note that a broad band light source (white light) must still be used. This is because of the sensor’s Bayer matrix. With this sensor, monochromatic (single color) light would have resulted in the individual pixels transmitting no or less information depending on the wavelength of the light, due to the RGB filter layers used (see Figure 2). This can result in a different brightness perception for the individual pixels. In this case, the RGB enhancement must be calibrated separately for R, G, and B. As a result, you then obtain an identical brightness perception for all pixels as with a mono sensor.

After RGB calibration (see RGB histogram, right) there is a homo-geneous brightness perception as with a mono sensor

Note: This RGB calibration is only valid for this specific light source and a “grey” scene. If the light source (wavelength) changes, the RGB enhancement factors have to be re-adjusted.

Contact 1stVision to obtain instructions on switching the Bayer matrix to “invisible” using the uEye Cockpit:2) For “color or grey scenes”

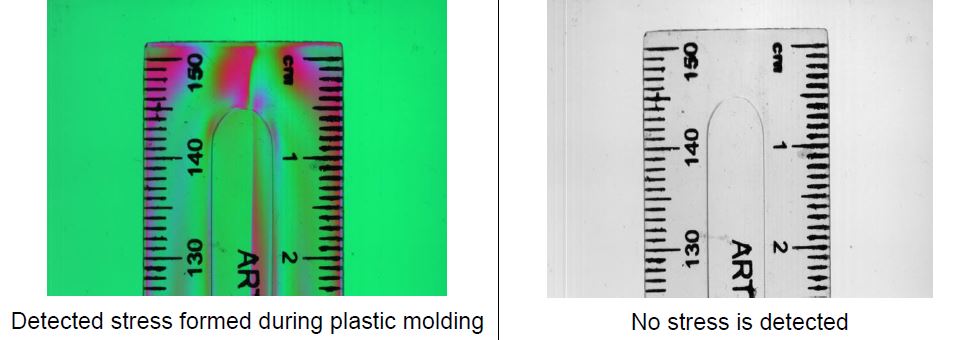

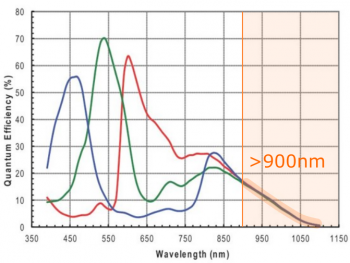

If you work with color scenes in your application, the brightness sensitivity of the individual Bayer pixels constantly changes with the variation in color components. There is also a way to achieve genuine mono mode in this situation. The solution lies in the color spectrum of the 18 MP ON Semiconductor AR1820HS.

Above a wavelength of around 900 nm the color filters for the individual pixels have similar spectral properties. Beyond this threshold, all pixels on the sensor respond practically identically to incident light again – exactly as with a dedicated mono sensor. This means that the Bayer matrix can also be made invisible using this method, both for color and also for grey scenes

In order to be able to use this spectral property of the sensor as described, you must observe the following:

- Ensure defined lighting conditions, i.e. seal off light with other wavelengths shorter than 900 nm as far as possible.

- Order your uEye camera with AR1820HS sensor specifically with GL filter (glass). The HQ filter normally ordered with this sensor would block out the long-wave light. By contrast, the GL filter allows light beyond 900 nm to pass with high transmission. The highest possible signal strength thus arrives at the sensor.

Full Information on the IDS Imaging UI-3590LE and UI-3590CP cameras can be found below

IDS-UI-3590LE – 18MP camera, LE version

IDS-UI-3590CP – 18MP camera, CP version

1stVision has over 100 years of industrial imaging experience! Contact us to help select the best camera and lenses for your applications.