We often are asked the question, “What is the difference between a global and rolling shutter image sensor in machine vision cameras? ” Although they both take nice pictures, they are very different image sensors with pro’s and con’s of each. In the end, rolling shutter image sensors cost less, but are not always recommended for moving objects.

We often are asked the question, “What is the difference between a global and rolling shutter image sensor in machine vision cameras? ” Although they both take nice pictures, they are very different image sensors with pro’s and con’s of each. In the end, rolling shutter image sensors cost less, but are not always recommended for moving objects.

In this blog post, we will explain the differences between global and rolling shutter sensors used in machine vision cameras. Additionally, we highlight how to use a rolling shutter camera capable of “Global Reset” providing low cost solutions for some applications with moving objects.

First, let’s explain the differences between rolling shutter vs global shutter image sensors in machine vision cameras.

Global Shutter: Image sensors with a global shutter allow all of the pixels to accumulate a charge with the exposure starting and ending at the same time. At the end of the exposure time the charge is read out simultaneously. In turn, the image has no motion blur on moving objects. This is given the exposure is short enough to stop pixel blur which is a topic for another blog.

Rolling shutter: Image sensors with a rolling shutter do NOT expose all the pixels at the same time. Alternatively, they expose the pixels by row with each row having a different start and end time frame. The top row of the pixel array is the first to expose, reading out the pixel data followed by the 2nd, 3rd & 4th row and so on. Each of the rows start and end point have a delay as the sensor is fully read out. The result of this on moving objects is a skewed image

What are the Pro’s and Con’s of each type of shutter?

Global Shutter:

Pro: Freeze Frame images with no blur on moving objects.

Con: Global shutter sensors require more complicated circuit architecture, thus limiting the pixel density for a given physical size. In turn, sensors with a global shutter will have a larger image format driving up lens cost. The complicated circuits also drive up the overall camera cost and will be more expensive vs a rolling shutter sensor.

Rolling Shutter:

Pro: Rolling shutter sensors have a simpler design with smaller pixels, allowing higher resolution in a smaller image format allowing use of lower cost lenses. The simpler pixel design results in lower camera costs!.. For example, Dalsa’s 18MP Nano for < $600!

Con: Image distortion occurs due to the row by row integration and offset on moving objects. Smaller pixels may also require a higher quality lens which is commonly gauged by the lens Modular Transfer Function (MTF). This is really dependent upon your application and can be discussed with a sales engineer. In turn, there maybe a small trade off to consider.

Is there a way to use a lower cost rolling shutter camera on moving objects? Absolutely using a Global Reset mode found in various image sensors.

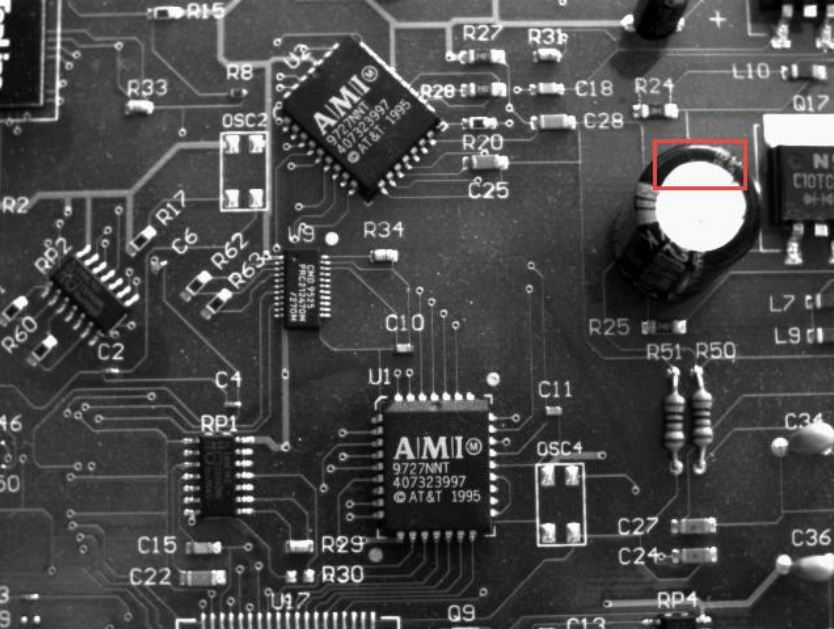

Using a rolling shutter capable of a “Global Reset” such as the AR1820HS found in the 18MP Teledyne Dalsa Nano C4900 camera will eliminate the image distortion.

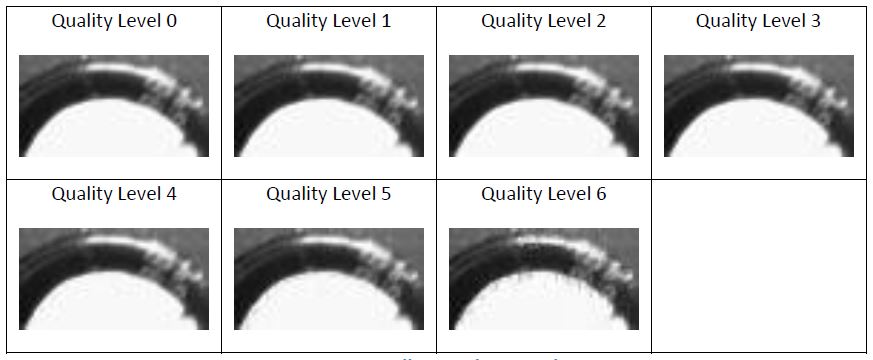

A typical rolling shutter image sensor as described above exposes sensor rows separately with a delay as depicted below.

Using a rolling shutter with global reset mode, all rows start integrating at the same time as shown below eliminating the image distortion. It is highly recommended however to use a dedicated strobe and sync with the start of image acquisition. A gradient in the image brightness from top to bottom maybe seen if not with some pixel blur due to longer row exposure

A great camera to consider is the 18MP Teledyne Dalsa Nano C4900 camera. This camera features the ON-SEMI AR1820HS sensor with this capability. With a price point of < $600, this makes it one of the lowest cost cameras per pixel on the market.

1st Vision has over 100 years of combined experience and can help you with camera, lens and other peripheral recommendations. If you have questions regarding the various sensor shutters, please do not hesitate to contact us!

Be sure to read our related blog posts:

What is a lens optical format? Can I use any machine vision camera with any format? NOT!

Demystifying Lens performance specifications – MTF

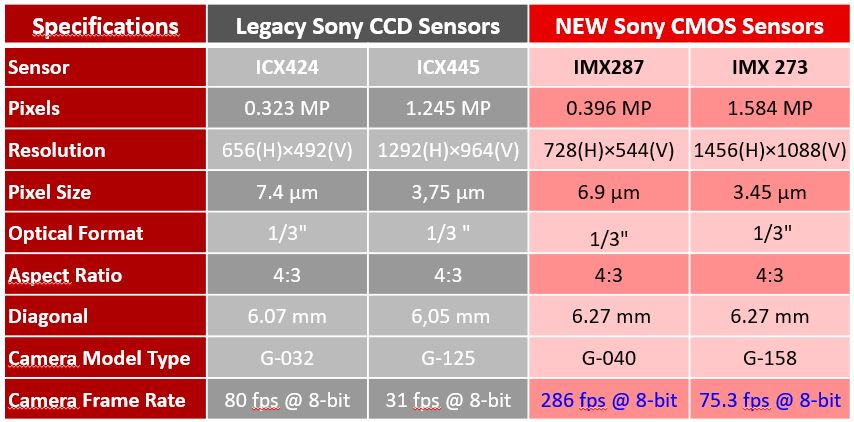

expanding its line of Manta machine vision cameras, releasing the Manta G-158 and Manta G-040 GigE Vision cameras. Featuring the second generation Pregius CMOS image sensors from Sony. These are great replacements for Legacy Sony ICX424 and Sony ICX445 image sensors found in the Manta G-032 and Manta G-125 cameras.

expanding its line of Manta machine vision cameras, releasing the Manta G-158 and Manta G-040 GigE Vision cameras. Featuring the second generation Pregius CMOS image sensors from Sony. These are great replacements for Legacy Sony ICX424 and Sony ICX445 image sensors found in the Manta G-032 and Manta G-125 cameras.

We often are asked the question, “What is the difference between a global and rolling shutter image sensor in

We often are asked the question, “What is the difference between a global and rolling shutter image sensor in