1stVision has the SWIR cameras you’re looking to find, including the Alvium 1800 series and Goldeye series from Allied Vision, and Teledyne Dalsa’s SL-GA series. Allied Vision Goldeye SWIR cameras feature InGaAs detectors with GigE or Camera Link interfaces for applications in automotive, biomedical, healthcare, and telecom, as well as in agriculture and agro-food industries. Their TE cooled design reduces dark current and improves signal to noise ratios for contrast-rich and highly stable imaging performance. Allied Vision Alvium 1800 SWIR cameras offer USB and CSI interfaces and feature compact size as uncooled cameras, with frame rates to 344fps. Teledyne Dalsa SWIR cameras are available with GigE interfaces and line scan imaging suitable for continuous motion application.

Since SWIR cameras can image through glass, they can be used to control and predict quality in semiconductor inspection, as well as in the detection of diseases, chemicals, microbials, liquids, and biological contaminants.

Except for individuals already familiar with imaging outside of the human-visible spectrum, SWIR imaging and its benefits may seem difficult to comprehend.

SWIR imaging systems use specially designed sensors, lighting, and lenses, with different materials than those used for visible light, to create digital image representations from the realm of Short Wave Infrared, from about 0.9 – 1.7 μm. Just as in traditional machine vision, applications may be developed whereby the image may be algorithmically analyzed to automate materials handling, quality control, real-time processing and other tasks.

Representative applications made possible by SWIR imaging:

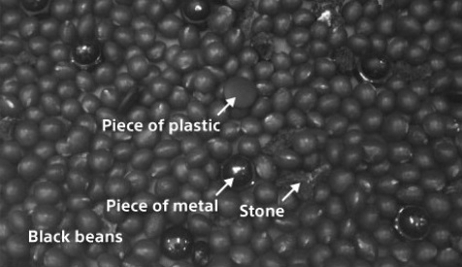

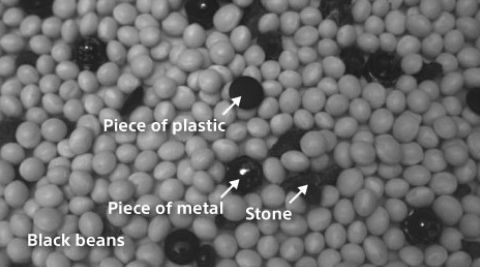

Consider the following two images. The left image, acquired in a visible imaging system, does not make it easy to distinguish that there are four different materials. But the right image clearly shows the black beans, the “keeper” product in this case, as distinct from the undesired materials. Whether for robotic sorting or quality control documentation, SWIR imaging opens up whole new ranges of applications.

SWIR cameras typically use InGaAs sensors, a compound of indium gallium arsenide which acts as a semi-conductor photon detector in the SWIR spectrum. Depending on the application, including duration of exposure and other factors, cameras using InGaAs sensor may be uncooled or cooled, which in turn influences their size, power consumption, cost, and performance characteristics. SWIR sensors are available in both area scan and line scan formats. As with most engineering solutions, one wants to get a solution that is certainly good enough, but without over-designing. Besides sensor and camera size, camera interface to the computer host must be considered. Popular interfaces include but are not limited to GigE, USB, CameraLink, and more recently CSI-2.

As with visible imaging applications, one must determine the field of view and necessary resolution, which will dictate sensor size as well as lens constraints and camera positioning. Will the object(s) or camera be in motion, or stationary? What exposure time is intended, and what are the shortest conceivable and longest conceivable exposure times? Do you know what software development kit (SDK) or package you will use? Will you do your own integration of camera, lens, lighting, fixturing, and software, or do you require integration assistance? If you are confident and experienced, there are many SWIR cameras to choose among. For assistance, contact us, as our sales engineers are seasoned professionals who take pride and helping our customers navigate the many options to an optimal SWIR vision system.

Learn more in our SWIR related blogs and white paper: