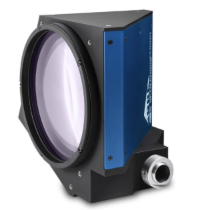

Opto Engineering TC CORE bi-telecentric lenses are designed for sensors up to 2/3”. They feature an ultra-compact size that's up to 70% smaller than other bi-telecentric lenses on the market without sacrificing high-end optical performance.

Opto Engineering TC CORE bi-telecentric lenses are designed for sensors up to 2/3”. They feature an ultra-compact size that's up to 70% smaller than other bi-telecentric lenses on the market without sacrificing high-end optical performance.

The distinctive shape of the TC CORE lenses offers utmost mounting flexibility. They can be mounted in various orientations using any of the four sides with or without clamps. This adaptability lowers system costs and makes installation or retrofitting easier, even in machines with limited space.

In addition, TC CORE bi-telecentric lenses can be combined with the ultra-compact LTCLHP CORE telecentric illuminators to create exceptionally small yet highly accurate measurement systems. This combination delivers both space efficiency and precision, making it ideal for applications where size and accuracy are critical considerations.

Opto Engineering telecentric lenses include a wide variety of lenses for area and line scan cameras. Contact us if you would like help choosing the right lens for your industrial machine vision applications.