IDS Imaging Ensenso 3D cameras and camera systems are built for industrial 3D imaging with a GigE interface for ease of setup. Ensenso 3D cameras are suitable for numerous 3D imaging applications including robotics, bin picking, warehouse automation and 3D measurement tasks. They are widely used for many industrial applications such as factory automation, logistics, and quality assurance.

Ensenso 3D cameras have numerous features, benefits, and options. Please contact us for more information. We can provide you with additional technical information and help you choose the right 3D camera system for your 3D imaging application.

Ensenso S Series 3D ultra-compact cameras are ultra-compact 3D industrial cameras that use 3D laser point triangulation with artificial intelligence to produce 3D data with high depth accuracy. They are a cost-effective solution for many budget-conscious and high volume 3D applications.

The N, C, B, X and XR 3D cameras are based on the stereo vision principle.

Ensenso N Series 3D cameras are compact 3D cameras that are specifically designed for harsh industrial environments and pre-calibrated for easy setup. N Series 3D cameras are "TM Plug & Play" certified by Techman Robot, and suitable for many 3D applications such as robotics and factory automation.

Ensenso C Series 3D color cameras are compact 3D cameras with color image sensors that supplement the 3D point cloud to produce more realistic looking 3D images. The pattern projector produces excellent pattern contrast even at long distances. 3D color improves the process of many 3D imaging tasks such as sorting, inspection, and surface inspection.

Ensenso B Series 3D color and monochrome cameras provide accurate depth measurements on objects at short distances - as close as 21 cm to about 2 meters. With a large field of view and high depth of field, the Ensenso B 3D camera ensures that objects remain in focus and sharp throughout the working area. They are built for robotics and other industrial applications where space is limited and precision is crucial.

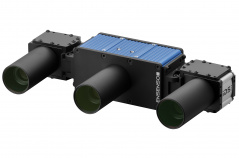

Ensenso X Series 3D ultra-flexible modular 3D camera systems are an ultra-flexible, modular, 3D industrial camera system with many configurable options that can be customized for your 3D application.

Ensenso XR Series 3D ultra-flexible modular embedded 3D camera systems feature on-board processing to reduce the network load making it an excellent solution for multi-camera systems, and many industrial applications such as factory automation with continuous production lines. Their ultra-flexible, modular design has many configurable options that can be customized for your 3D application.

The Ensenso N, C, B, X and XR Series 3D cameras and camera systems produce 3D data based on the stereo vision principle. Stereo vision emulates human vision with two cameras focused on the same object from different vantage points. Closing one eye and then quickly opening the eye while closing the other eye is an example of how two cameras work from different vantage points.

High-contrast textures are projected onto the object(s) to be imaged with a pattern mask to build a disparity map (a map of the pixel difference between a pair of stereo images) to analyze the object's surface.

For static objects Ensenso cameras improve on the stereo principle with FlexView technology. With the mechanical system's piezoelectric actuator the projection rays are shifted linearly in small increments to produce varying textures of an object's surface which captures multiple image pairs with significantly more pixels and structural details even on reflective, glossy or dark surfaces. The result is higher resolution, low noise 3D disparity images with more point clouds. The higher quality data also reduces the time required for post-processing.

Learn more about 3D data with stereo vision.

This video demonstrates how Flexview how the mechanical system's piezoelectric actuator shifts the pattern linearly in small increments to produce varying textures of the object's surface which captures multiple image pairs with more pixels and structural details. A matching algorithm processes the image pairs. The result is that the data from the disparity map is improved with higher resolution 3D images and less noise.

This video illustrates measurement and inspection tasks using FlexView for quality control to count gear teeth. Click and hold on the video to move and examine the object.

This video depicts image acquisition without FlexView at a high data rate. It illustrates how 3D cameras can be used in industrial applications such as in bin picking. Click and hold on the video to move and examine the object.